Factory Z183 (83 Mechanical One Member Limited Liability Company), under the General Department of Defence Industry (GDDI), is tasked with producing and repairing artillery shells of various types, manufacturing materials for ammo packing and storage, as well as water industry and firefighting products for both domestic and foreign markets.

|

| GDDI leadership during their working visit to the Factory |

In addition to advantages, the Factory has been confronted with a lot of challenges and difficulties caused by the increasingly high requirements of defence production; its economic products face intense competition both at home and abroad; resources for production and business, including human resources, technology, equipment, and facilities, have yet to keep pace with the development of its tasks. Against that backdrop, with great resolve and knowledge of “Uncle Ho’s Soldiers” on production front, the Factory’s Party Committee and Board of Directors (BOD) have drastically taken various measures to improve the Factory’s competitiveness, production and business efficiency, and prestige in the market.

First of all, the Factory has enhanced all-level party committees and commands’ leadership and direction over production and business tasks. The Factory’s Party Committee and BOD have grasped higher echelons’ resolutions and directives, particularly the 13th Politburo’s Resolution 08-NQ/TW, dated 26 January 2022, on defence industry development towards 2030 and beyond as well as Resolution 426-NQ/ĐU, dated 28 March 2022, by the GDDI Party Committee on leadership over economic production and export towards 2030. Grounded on those documents, they have issued and effectively implemented Resolution 254-NQ/ĐU, dated 10 June 2022, on leadership over economic production and export towards 2030, Strategy for defence production development towards 2030, Strategy for production and business development in the period of 2025 - 2030, and other relevant plans in sync with the Factory’s long-term goals and practical conditions. They have established the goals of building a modern Factory capable of manufacturing and repairing artillery shells in service of the Military, exporting defence products, manufacturing economic products for both domestic and foreign markets, forming an extensive network of markets and customers, becoming one of the world’s top enterprises in producing materials for packing and preserving ammo, and ranking number one in Vietnam for manufacturing and supplying firefighting equipment and materials. To realise those goals, they have stepped up the streamlining of its organisational structure, reducing its intermediate units, merging its sections with similar functions and tasks, increasing direct labour, ensuring the “compact, effective” operations of its offices and units. The Factory has upheld and promoted the “seven dares” spirit among its cadres and party members, particularly heads of offices, boards, and production workshops, carrying out the decentralisation of authority, aligning responsibility of all-level party committees and commands with the performance of their assigned tasks. At the same time, consideration has been given to enhancing political and ideological education to raise awareness and achieve consensus among all cadres and employees about the Factory’s development orientation and model, thereby encouraging all staff members to dedicate themselves to the Factory.

Furthermore, the Factory has focused on developing human resources to meet its long-term and short-term task requirements. Under Resolution 33-NQ/ĐU, dated 3 October 2020, by the Factory Party Committee on leadership over the building of a pool of cadres, particularly heads of offices, boards, and production workshops and technicians to meet the new task requirements, over the years, the Factory has directed its affiliates to review and correctly evaluate this contingent as the basis for personnel planning, training, and development, particularly in science and technology fields. It has actively renewed the work of training and retraining, combining this work with the sharing of hands-on experiences via its operational processes, increasing contests in tandem with the emulation movement of “good labour, creative labour”. Notably, it has collaborated with Hanoi University of Technology and National Economics University to organise refresher courses for its cadres at all levels, encouraging its staff members to self-study and improve their professional expertise, building a democratic, equal, favourable working environment for its cadres and employees to better themselves. Thanks to those approaches, up to now, all cadres of the Factory have held a bachelor’s degree or higher; 50% of them have been masters; 62.2% of its technical employees have held an intermediate vocational degree or higher; more than 50% of its skilled workers have achieved level 5 out of 7 levels. Those human resources have been significantly contributing to improving the Factory’s production and business capacity and fostering the Factory’s sustainable development.

|

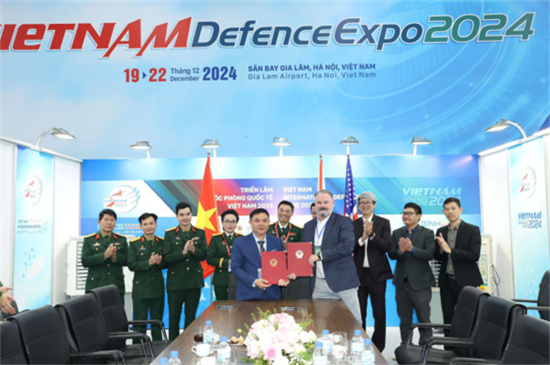

| The signing of an export contract between the Factory and its foreign partner during Vietnam Defence Expo 2024 |

In response to the increasingly high requirements of productivity and product quality, the Factory has invested in modernising its production lines, technical equipment, and infrastructures. Adhering to the development of armaments and market needs, the Factory has proactively made recommendations to the GDDI on upgrading its infrastructures and acquiring dual-purpose, modern production lines and equipment. At the same time, it has synchronously upgraded all workshops and facilities to meet its demands for expansion of production scales and improve the working conditions for its staff members. Since 2020, it has proposed and completed 20 projects, making a positive change in its appearance and production and business capacity, meeting the development of its tasks and the strict requirements set by its partners. It has also attached importance to science research and technical initiatives and innovations to raise its production capacity and work towards self-reliance in technology. Annually, based on collective and individual commitments, the Factory Initiative Council has appraised and selected highly feasible initiatives and research projects to provide funding. Simultaneously, the Factory has issued many special policies to opportunely commend collectives and individuals with outstanding achievements in science research and technical innovation. Since 2019, it has undertaken 400 research projects and initiatives; many of them have won top awards at GDDI, Army-wide, nation-wide levels, greatly contributing to raising its production and business capacity and efficiency.

To keep asserting its position and raising its competitiveness in the market economy, the Factory has diversified products and improved professionalism and effectiveness in corporate management. Under the Strategy for defence production development towards 2030 and the Strategy for production and business development in the period of 2025 - 2030, over the years, the Factory has researched and developed new strategic products to achieve stability in the production and business process. As for defence production, it has researched, manufactured, and repaired 15 products, including 6 new ones and several types of artillery shells at operational level. It has also focused on enhancing the quality and credibility of its products. It has actively designed smart, advanced weapons and ammo, while striving to export defence products. Regarding economic production, it has concentrated on developing metal boxes for ammo, diversifying water industry and firefighting products, and working on integrated smart solutions in the following period. A part from its traditional partners, it has been seeking new partners and foreign markets. It has applied pieces of modern administration software, such as Enterprise Resource Planning (ERP) in the military network environment and Manufacturing Execution System (MES), conforming to quality management systems, i.e. TCVN ISO 9001:2015 and other international standards to enable its products to be exported to new markets. It has implemented Kaizen and 5S programs to make positive changes in scientifically arranging its premises and improving its production efficiency. Doing so has also allowed the Factory to optimise steps of production, reduce costs, labour, and product prices, and increase its productivity, product quality, and competitiveness in the market.

In addition to those above-mentioned measures, the Factory has strictly maintained safety regulations and improved the working environment for its staff members. Due to the particularities of its production operations, the Factory has required offices and units to frequently conduct inspections to opportunely detect and deal with risks, stringently maintain safety regulations, especially during ammo transport and storage, well organise training courses and exercises on fire and explosion prevention and control, and carry out propagation to raise awareness and a sense of responsibility among all staff members in this regard. Since 2020, it has spent 16 billion VND (a 900% increase compared to the previous period) upgrading its electricity, dust extraction, fume extraction systems, constructing new wastewater treatment systems, and improving its landscape design, thereby achieving breakthroughs in the environmental quality and working conditions for its staff members.

Thanks to those above-mentioned synchronised, breakthrough measures, Factory Z183’s production and business capacity and efficiency have been significantly improved as a solid prerequisite for the Factory to become a core, modern defence industry facility capable of excellently accomplishing all assigned missions.

Sr. Col. BUI VAN LUONG

Secretary of the Factory Party Committee

Director of the Factory